Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

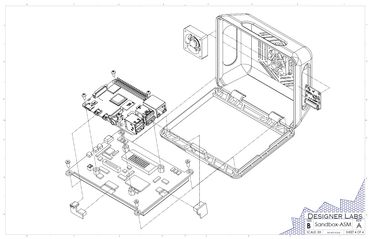

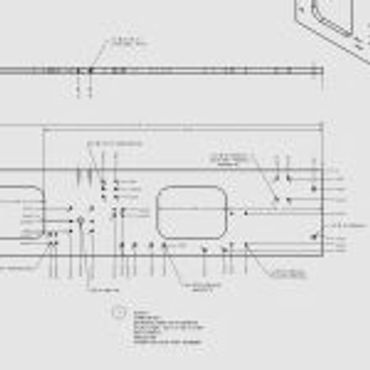

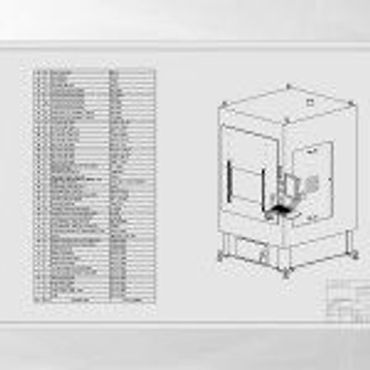

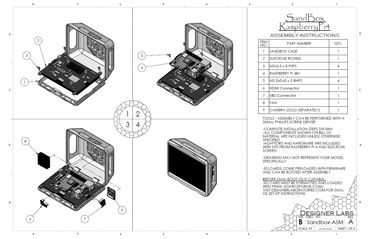

This is where innovation meets precision, and chaos meets order. First, you'll find engineering and business information, and then some design samples. The designs at the bottom are the result of two decades of experience crafting bespoke machine designs, tailored to meet the unique needs of companies across various industries. Whether you're in high volume manufacturing, aerospace, or just an individual that needs a prototype for that invention in your closet, DLabs solutions can optimize efficiency and enhance performance, driving success.

From concept development to prototyping and final production, send an email or place a call to 248-563-6383, and start leveraging years of design resources and expertise to bring your vision to life.

Unlock Your Business Potential with Designer Laboratories:

Are you ready to take your business to the next level? As a leader of your company, you understand the ins and outs of your operations like no one else. However, there's always room for improvement, and that's where Designer Laboratories comes in. I'm here to sit down with you and have a candid discussion about your facilities, your business goals, and how my skills can be leveraged to drive meaningful enhancements.

Together, we can explore innovative solutions tailored to your unique needs, whether it's streamlining processes, enhancing product quality, or boosting efficiency. Let's schedule a one-on-one consultation to brainstorm ideas and chart a course towards a brighter future for your business.

Contact today via email at AjArtifex@gmail.com or phone at (248)563-6383 to set up a consultation. Let's collaborate to unleash the full potential of your business and propel it towards success.

Today | By Appointment |